Weigh and label carcasses, combos, cases and more with ease…

iCap Product Weighing and Labeling

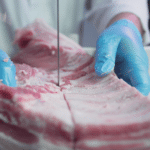

iCap is the industry’s most comprehensive and robust plant floor weighing and labeling solution. It’s designed to handle virtually any weighing or labeling challenge a food company can throw at it. iCap can be found all across a plant. On the kill floor operators use it to capture carcass weights. On the cut-floor iCap captures the weights of WIP combos and cases. In the packaging area, iCap weighs and labels finished good cases and pallets. It functions as both a standalone application and as a centrally managed data capture solution controlled by Carlisle’s Symphony Traceability Software.

ICAP – STATIC WEIGHING AND LABELING

ICAP – AUTOMATED WEIGHING AND LABELING

Ideal for larger, high-volume processors, iCap InMotion offers all of the same capabilities as iCap – Static. iCap InMotion adds automated features that are key to this operator free application. Inbound product can be identified with fixed scanners which automate the selection of the correct product. When the product passes over the scale the product weight is captured and iCap instructs a label applicator (1 or more) to apply the appropriate label(s) on to the box. Advanced features like automated product rejection and sortation are also available.

Work In Progress Tracking

Work in progress tracking is crucial. Especially when it comes providing a meat processing plant with an end-to-end traceability solution. Carlisle Technology’s Symphony WIP Tracking Solution allows a plant to create production batches and keep an accurate record of all raw material issued to each production batch. Symphony’s WIP Tracking Solution also associates production outputs, like intermediate products and finished goods, to specific production batches. With this solution, management has a complete view of every production batch from raw material inputs through to finished goods outputs.

Live Animal Receiving and Carcass Processing

Symphony’s Harvest Module, paired with iCap’s Hot Scale and Cold Scale applications combine to create a fully integrated data capture solution. This solution provides real-time carcass tracking capabilities as a carcass goes from one stage of the kill process to the next. iCap enables a plant to maintain carcass traceability throughout the kill process. iCap also integrates directly with RFID wands, Rail Scales, Trolley Vision, and Industrial Printers.