Symphony WMS: Order Fulfillment

Simplicity and efficiency are key when it comes to order fulfillment. Carlisle Technology’s Symphony WMS streamlines the entire order fulfillment process. With Symphony’s Order Management Dashboard, office personnel can track orders from the initial order entry through shipping. As a fully integrated solution, Symphony WMS sends picklists to the warehouse with the simple click of a button. Operators receive the picklists on handheld mobile computers running Symphony Mobile. When an order has been filled, the picker passes the control back to the office so they can finalize all the shipping paperwork. Order fulfillment can be an intricate process. Symphony WMS was built with the flexibility to handle almost any situation that might arise.

This product description walks the reader through a high-level overview of the main solution functions. There are two specific pieces to Symphony’s Order Fulfilment and Inventory Management Solution.

The first piece of the solution is Symphony’s web-based Carlisle Information Portal. This portal can be accessed by users with a connection to the processing plant’s network. The portal provides the user with access to front office applications like the Order Management Dashboard, and the Order Entry Application. The Carlisle Information Portal also includes setup screens, management reports, and system configuration settings.

Symphony Mobile is the second piece of the solution. The mobile application operates on a handheld mobile computer. Symphony Mobile allows operators to receive picklists, fill orders, cycle count inventory locations, build pallets, and more.

Solution Overview:

- Order Management Dashboard

- Sales Order Entry

- Order Picking

- Order and Truck Closing

Order Management Dashboard

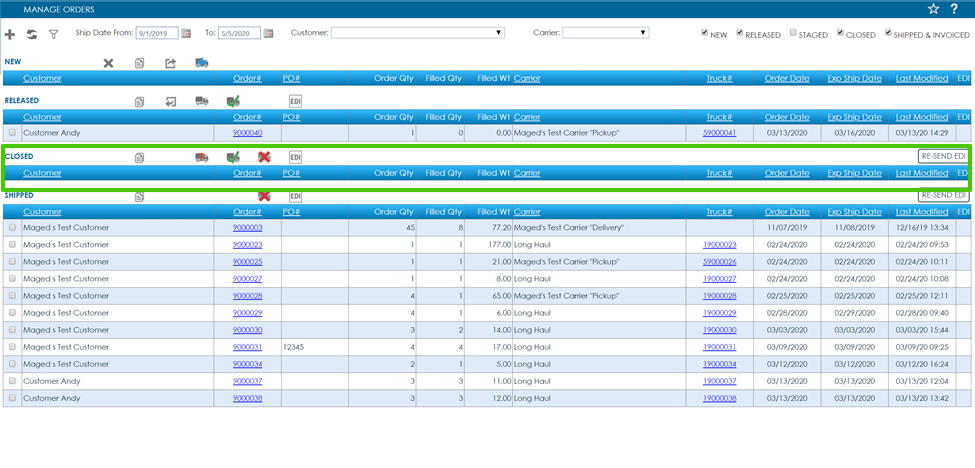

The Order Management Dashboard gives office personnel a single screen with which they can manage an order from start to finish. The Order Management Dashboard prevents the user from having to jump between multiple applications to complete an order. From the Order Management Dashboard, the user can enter new orders, release orders to be picked, monitor the status of orders currently being picked, and close orders/trucks. The Order Management Dashboard also allows users to print invoices and the shipping paperwork for each order.

Sales Order Entry

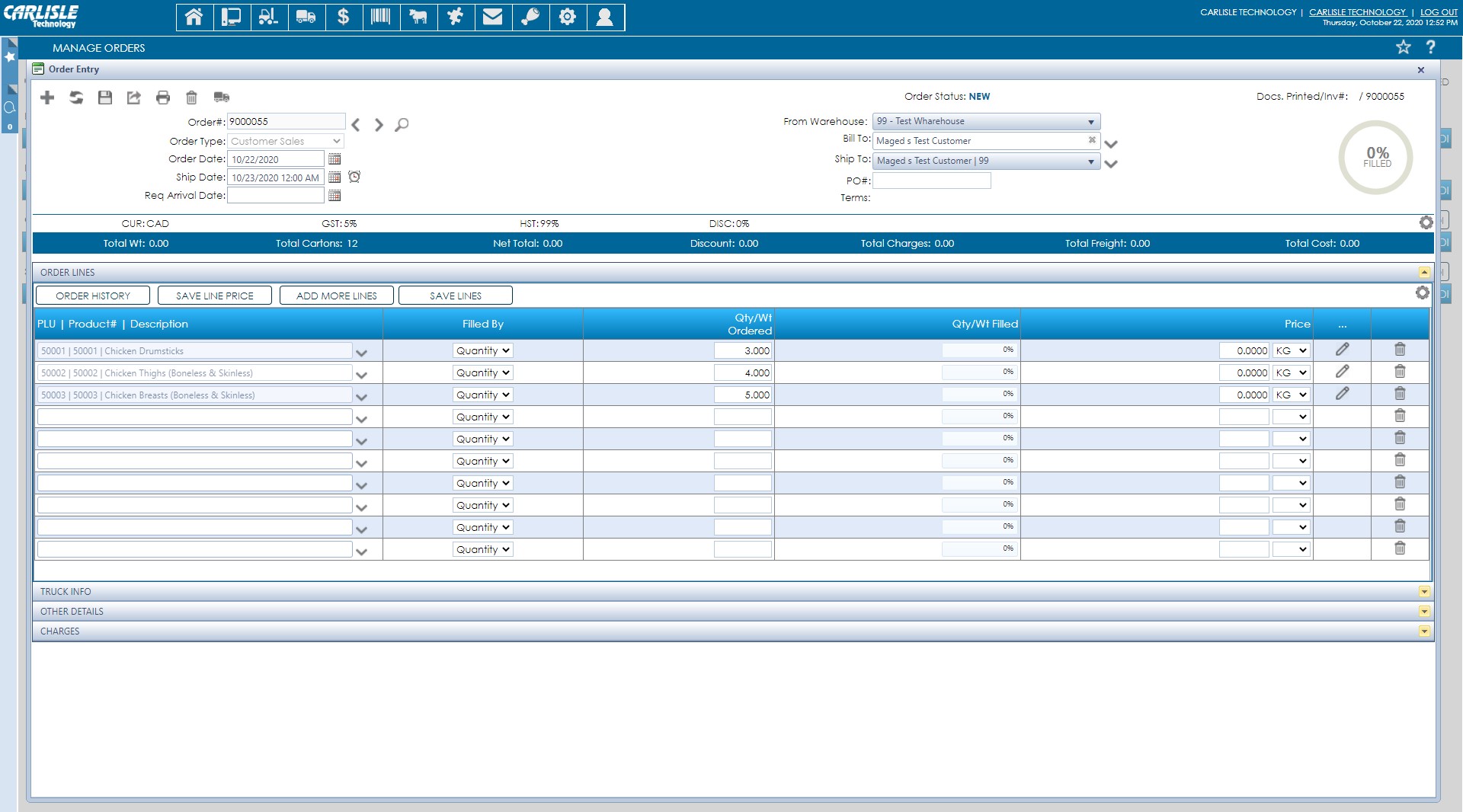

From the Order Management Dashboard, users can create a new sales order with the Sales Order Entry Application. By clicking the “+” button at the top of the Order Management Dashboard, a new window will pop-up over the top of the dashboard.

The Sales Order Entry Application was designed to make the process of entering an order as efficient as possible. At the top of the screen, there is a row of action buttons. These buttons allow the user to do various actions like start a new order, save the current order, and release the order for picking. Directly underneath the action buttons is the order-header information. The order-header section includes common information like the customer’s “Bill To” and “Ship To” address, purchase order number, and the payment terms.

Line items can be added to the order by keying in the item’s description, PLU, or product number. Each line item search field features “look-ahead” search functionality. Based on the characters being entered into the search field, “look ahead” search functionality predicts what the user is going to type. This functionality helps simplify entering line items into an order. “Look ahead” search functionality can also help by predicting what the user is looking for when they can’t remember the entire description or PLU number.

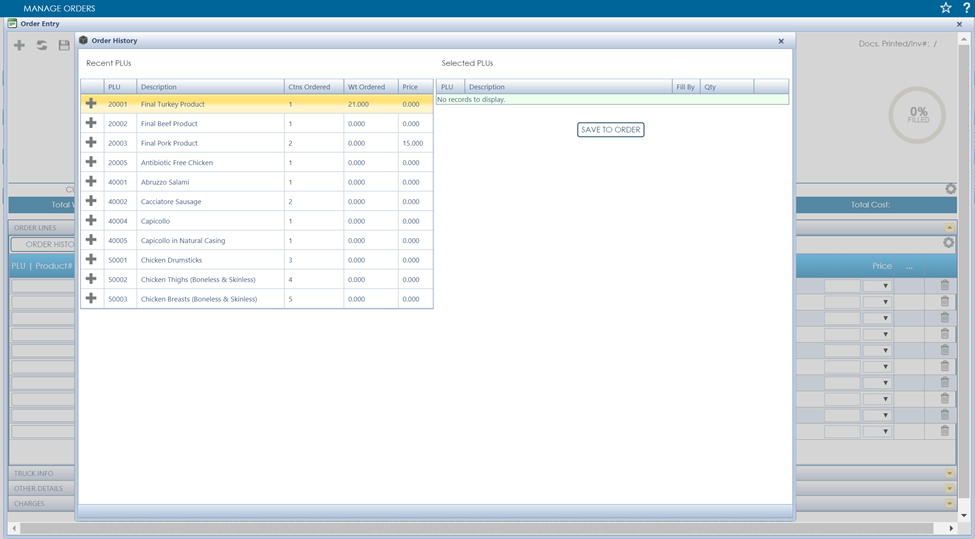

Order History

Since it is common for customers to regularly order the same products, Symphony’s Sales Order Entry Application allows the user to look into each customer’s history and add recently ordered products to a new order. To add line items from previous orders, the user selects the Order History button. This will pull up a new window over the Sales Order Entry screen. Users can select which products to add to the new order, adjust the quantities (if needed), and save the selected products to the new order. Once all the line items have been added to the new order, the user saves the order and closes the Sales Order Entry Application.

Order Picking

The Order Management Dashboard will display new orders under the row labeled New. All New orders can be viewed by a specific date range. This allows users to look at past, current, and future orders.

The Order Management Dashboard makes it simple to release an order for picking. When one or more orders are ready to be picked, the office user can select each order and release the orders to the warehouse for picking. All the released orders will appear in the Released row on the Order Management Dashboard. The orders will also appear in the Symphony Mobile Application operating on the handheld mobile computers in the warehouse.

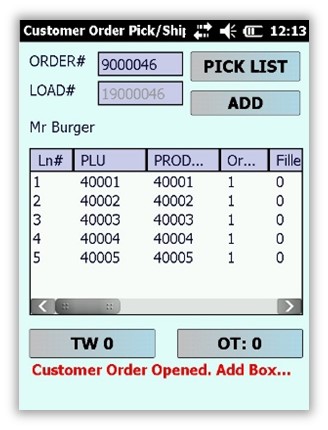

Symphony Mobile – Order Picking

Symphony Mobile operates on the handheld mobile computers in the warehouse. The Symphony Mobile user can build cartons or pallets, cycle-count inventory, and pick orders for shipping. After an order has been released for picking, the Symphony Mobile user will be able to start filling that order. Office personnel can monitor the progress of an order being picked from the Order Management Dashboard.

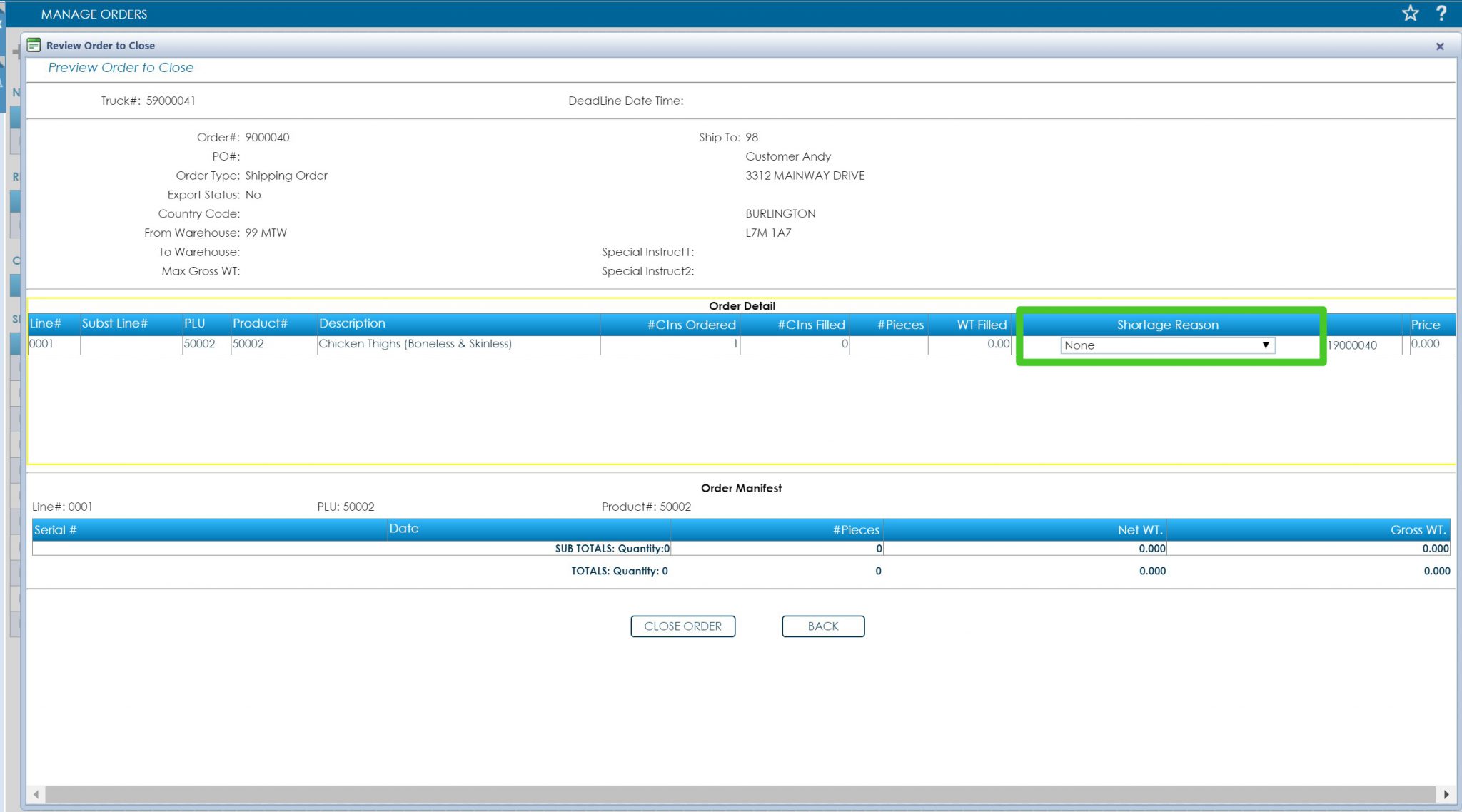

Order and Truck Closing

When the Symphony Mobile user completes the picking process, they must pass control of the order back to the office. In the office, the user can review and approve the order by selecting the order and selecting the Approve Truck action button. An order must be reviewed before it can be approved and closed. The office user will need to give a shortage reason for any order line items that weren’t completely filled. The user can select and close the order after reviewing it by selecting the Close Order button.

The order will now move from the Released row, on the Order Management Dashboard, to the Closed row. All orders will stay in the closed row until the user is ready to print the invoice and shipping paperwork.

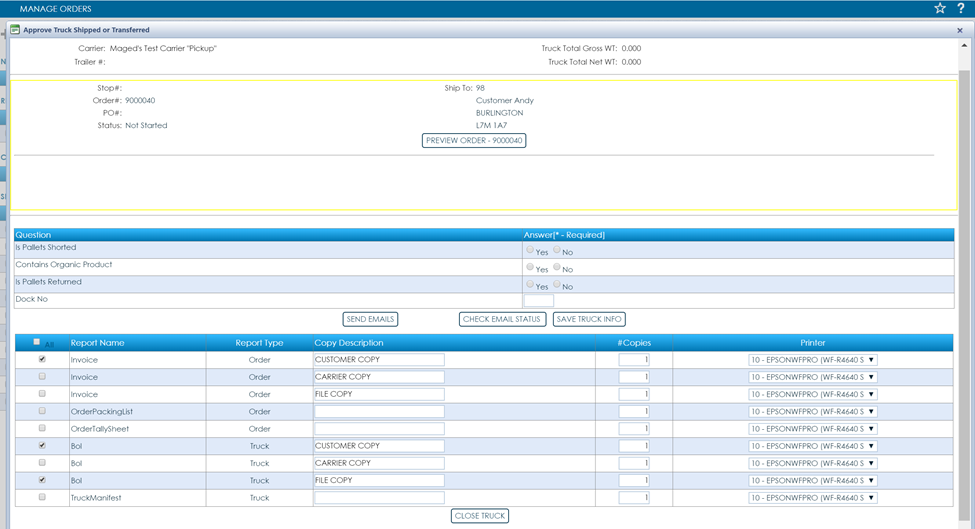

Truck Closing

Closing a truck is the final step in the order fulfillment process. Symphony can be set up to include truck questions as part of the truck closing procedure. Truck questions are a series of configurable questions designed to gather relevant information about a shipment. To close a truck, the orders need to be approved, and the truck questions need to be answered. Invoicing and shipping paperwork can also be printed during this final step.

Carlisle Technology: Our Expertise

Over the years, Carlisle Technology has steadily responded to the needs of the food industry by adding product features, application configurability, scalability, and ERP System integration. Today, Carlisle’s focus is on full-featured, plant-wide, integrated software and hardware solutions that meet the needs of the Food Processing Industry from receiving to shipping and order fulfillment. Carlisle Technology provides and supports fully integrated plant floor data collection and inventory solutions, which enable full internal traceability as well as process visibility. Due to Carlisle’s broad expertise, maintaining or improving productivity during the data collection process is a key consideration in all our systems.